STEAM TRAP PERFORMANCE TESTING & MONITORING

efficient and safe plant operation includes steam trap and condensate management systems operating at their peak performance and cmi services can help ensure system reliability

be sure your condensate isn’t getting backed up

Integral to an effective condensate management system, steam traps are automatic valves designed to discharge condensate, and vent air, while minimizing the loss of steam. Depending on facility size, improperly maintained traps can result in steam system efficiency losses which equate to tens or even hundreds of thousands of dollars per year. As with all mechanical devices, steam traps are subject to wear that will eventually require maintenance or replacement to restore operation in accordance with manufacturers specifications and prevent such issues as steam leakage or blocked condensate discharge (resulting in cold steam traps and possible frozen/split tracers and piping).

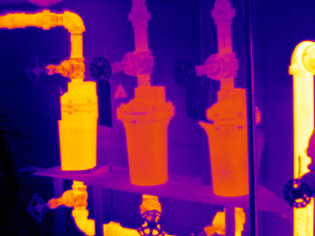

CMI Services uses its proven workflow system consisting of two-step field verification for suspect traps to ensure our customers realize maximum value from their steam management program. By utilizing a combination of proven digital instrumentation and thermography, we will determine the state of your condensate system with the highest level of confidence. And when our customers are looking for a full “turn-key” solution, CMI Services can deliver with seamless scheduling, execution, history capture in our database and reporting of testing results as well as repair/replacement of underperforming traps with closeout documentation. If a thorough and well documented steam trap program is required at your facility, than let CMI Services manage the task for you.